Introduction

This document has been prepared to address the common questions related to differences between 4Ab heads vs. 9Ab heads.

Background

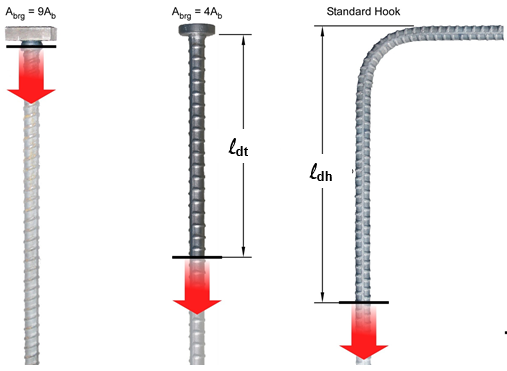

Heads or headed bars are commonly described or referred to based on bearing area.

4Ab head

- Standard head in the US today – required by ASTM A970 and ACI 318.

- Net bearing area of at least 4 times the nominal area of the bar (Abrg ≥ 4Ab). The net bearing area equals the area of the head minus the nominal area of the bar (Abrg = Ahead - Ab).

- Gross bearing area (including area of the bar) ≥ 5Ab.

9Ab head

- Was the standard in the US prior to 2004 (reference historical versions of ASTM A970), and are still used in some applications today.

- Standard head in Europe and Canada today.

- Net bearing area of at least 9 times the nominal area of the bar (Abrg ≥ 9Ab). The net bearing area equals the area of the head minus the nominal area of the bar (Abrg = Ahead - Ab).

- Gross bearing area (including area of the bar) ≥ 10Ab.

HRC Products

4Ab head

9Ab head

- HRC 100 Series T-Headed Bars (#5 - #18)

- HRC 200 Series T-Headed Bars (#5 - #18)

- HRC 670L Series HeadLock T-Heads (#5 - #18)

Application

4Ab head

- Partially bond dependent, like hooked bars (development length required).

- Anchorage of reinforcing bar is provided through a combination of bond (development length) and bearing.

- Used to terminate reinforcing bars in lieu of a standard hook (replace standard hooks), improve constructability and reduce congestion.

- In most cases the installation parameters for the headed bar are the same as the hooked bar they are replacing, but ACI 318 Code does allow for a shorter development length when using heads.

- Cannot be used when 9Ab heads are required by design.

9Ab head

- Bond independent (no development length required).

- Anchorage of reinforcing bar is provided through bearing alone directly beneath the head.

- Used to terminate reinforcing bars when point of maximum stress is close to the end of the bar, when development length leading up to the head is neglected during design or when member depth/width doesn't accommodate required development length for 4Ab head.

- Can be conservatively used when 4Ab heads or standard hooks are required by design.

Visual Product Comparison

4Ab vs. 9Ab – Fixed Head

4Ab vs. 9Ab – Field Installed Head

Warning

HRC products are designed to meet and exceed the standards referenced in this document, but individual project specifications and quality control requirements apply. HRC destructively tensile tests finished products daily as part of our quality control, but cannot be responsible for material furnished by local fabricators and/or contractors using HRC related equipment or components. Aspects of structural design, evaluation of product fitness for use, suitability or similar attributes are the responsibility of others.